Haining Aite Clothing Co., Ltd

Company Profile

One-stop OEM/ODM manufacturer

Founded in 2009 in Haining, Zhejiang, Haining Aite Clothing Co., Ltd. is a one-stop OEM/ODM manufacturer focused on seamless garments. Operating a 15,000 m² (≈161,000 ft²) plant with 250+ staff, we run Italian Santoni seamless knitting lines supported by 80 sewing machines, 8 industrial pressing stations, 3 in-line QC lines, and 3 high-efficiency packing lines—delivering 350,000+ pcs/month. Our portfolio covers men’s, women’s and kids’ seamless underwear, yoga wear, tanks, shapewear and base layers, exported to Europe, the U.S., Southeast Asia and South Africa. From design and sampling to pilot builds and mass production—under NDA when required—we pair engineering rigor with responsive service.

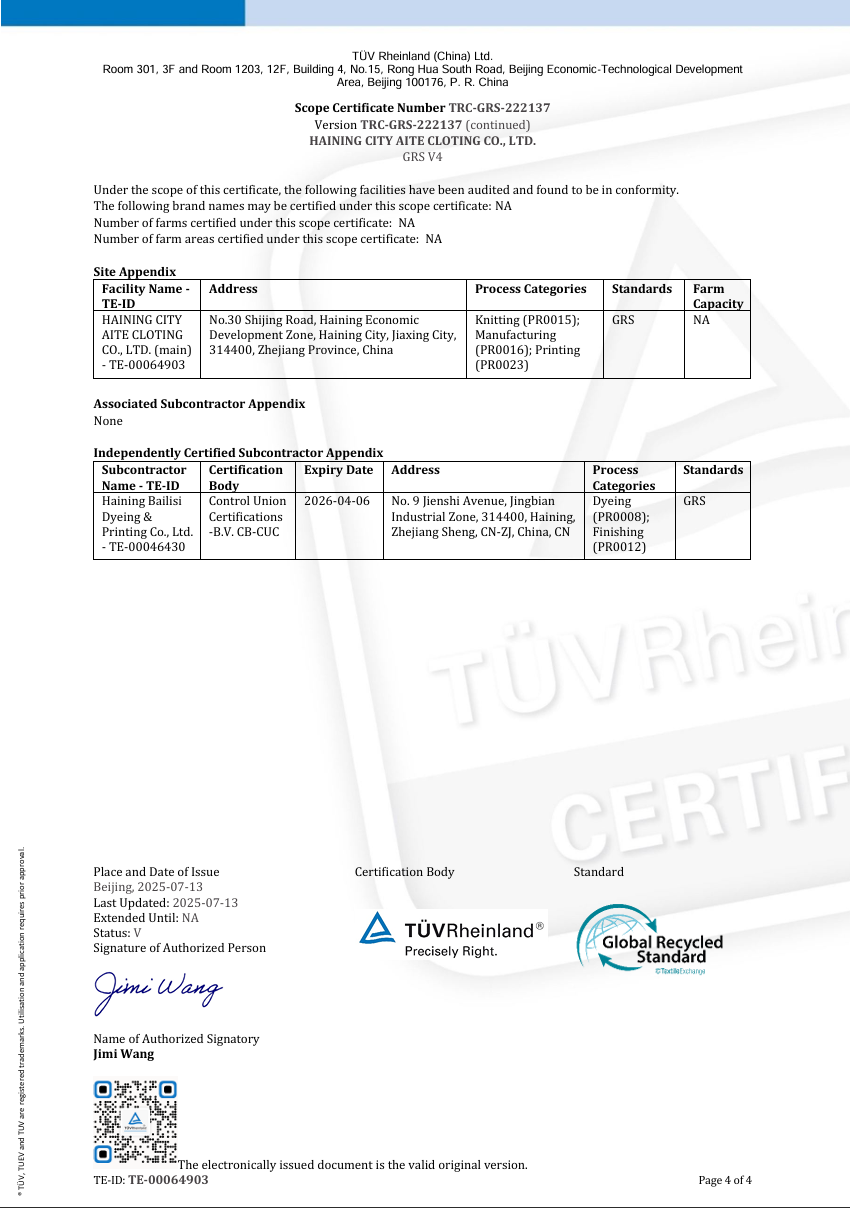

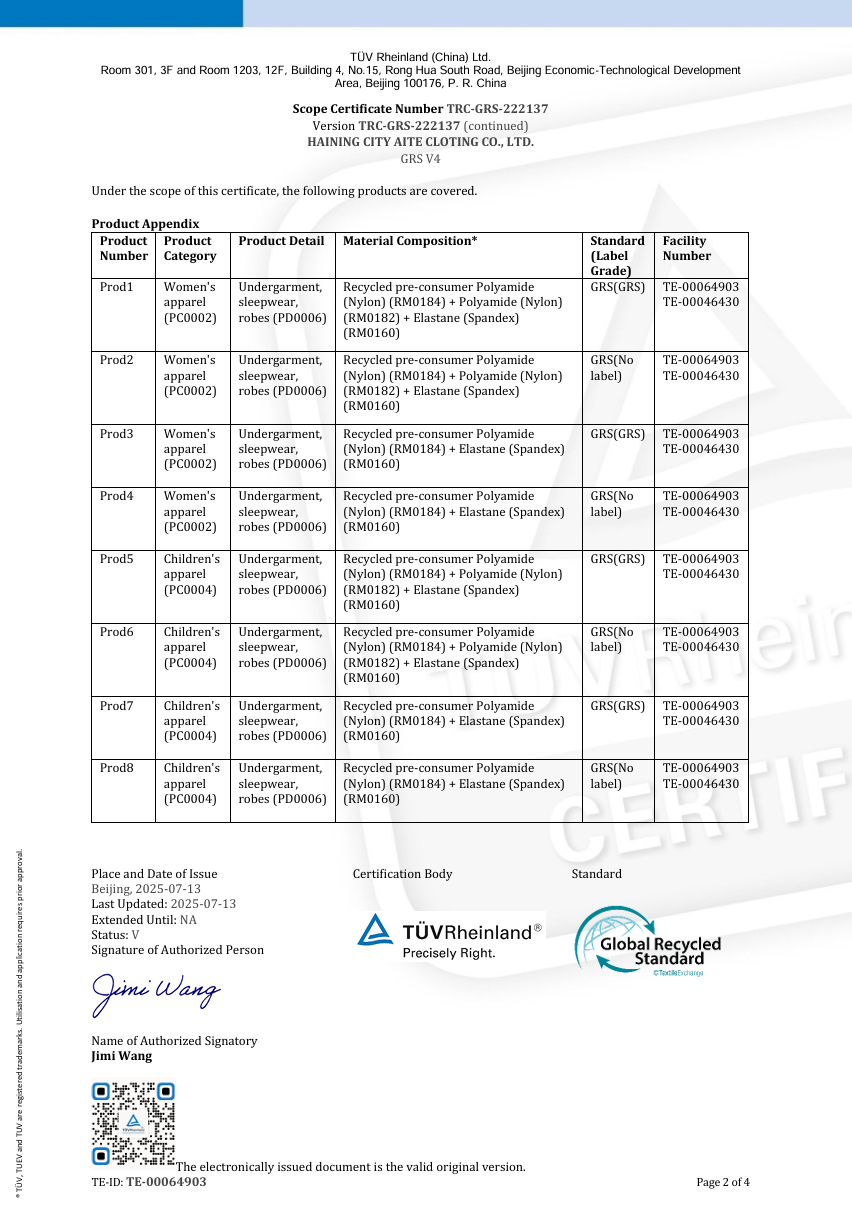

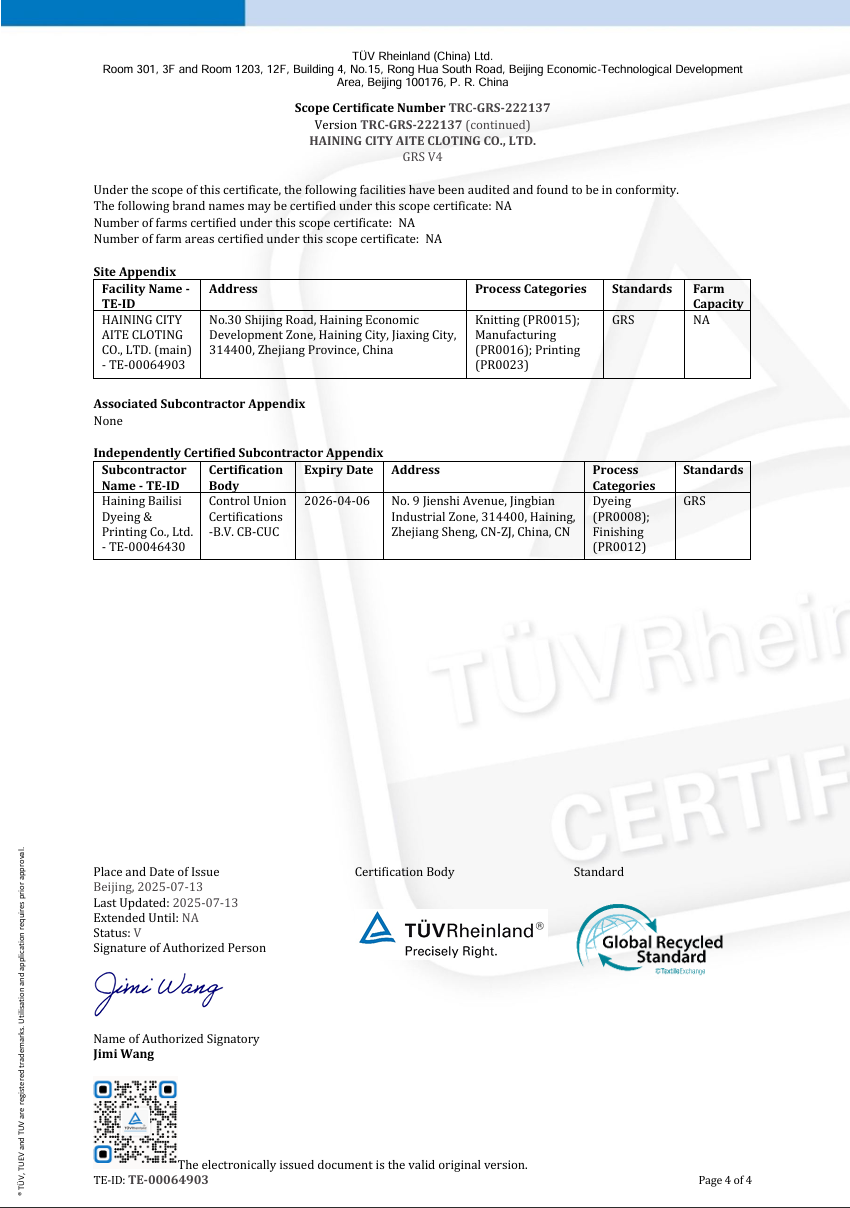

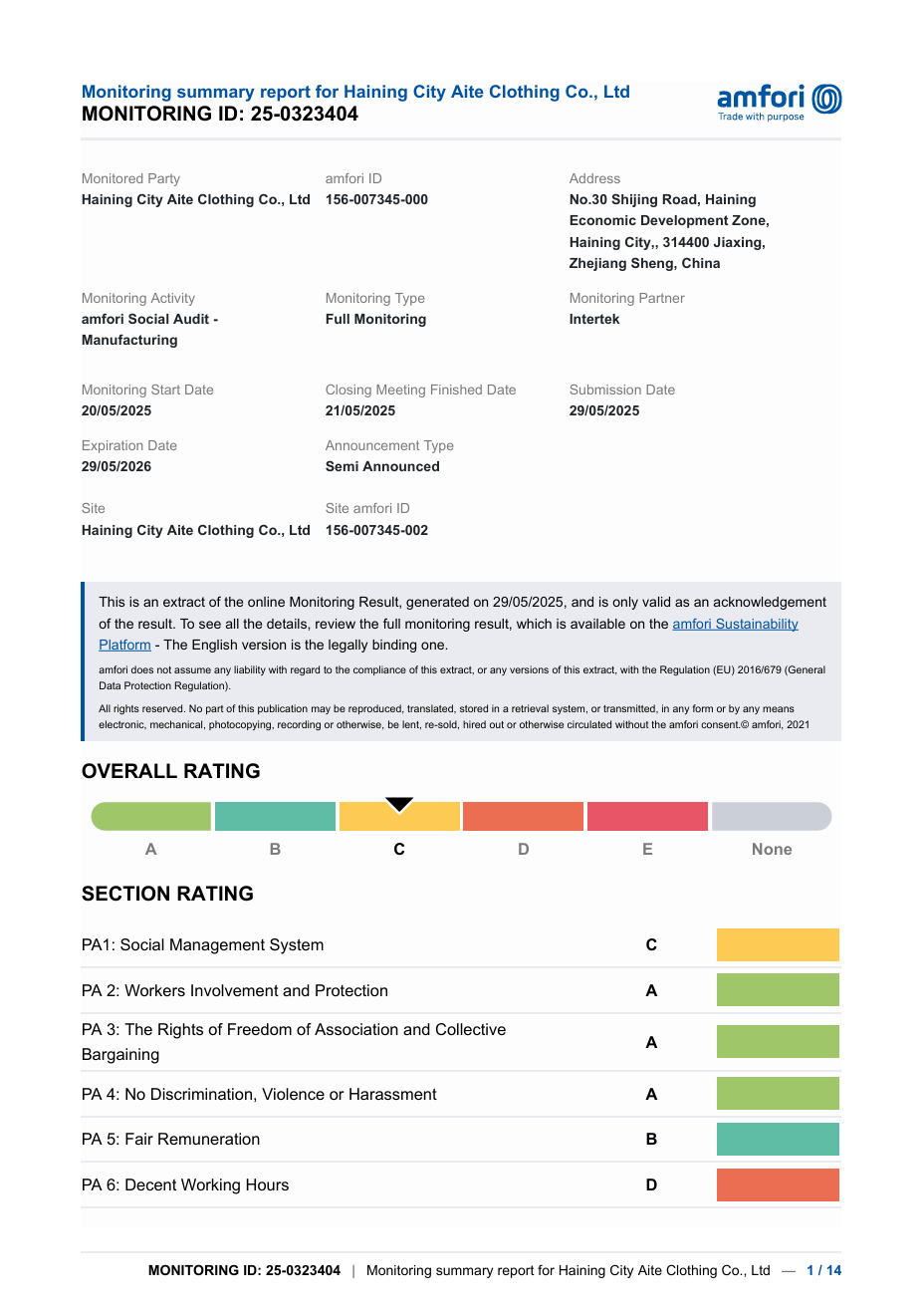

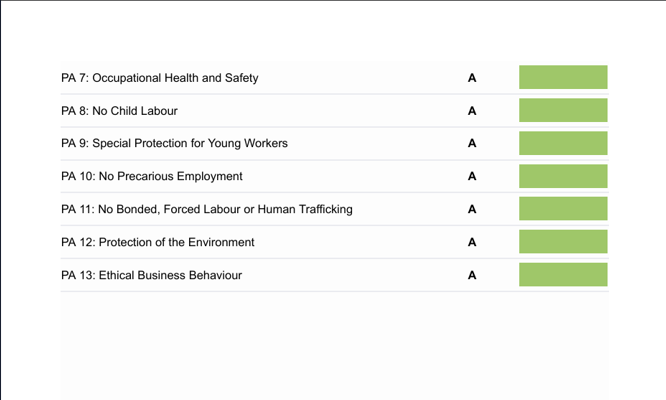

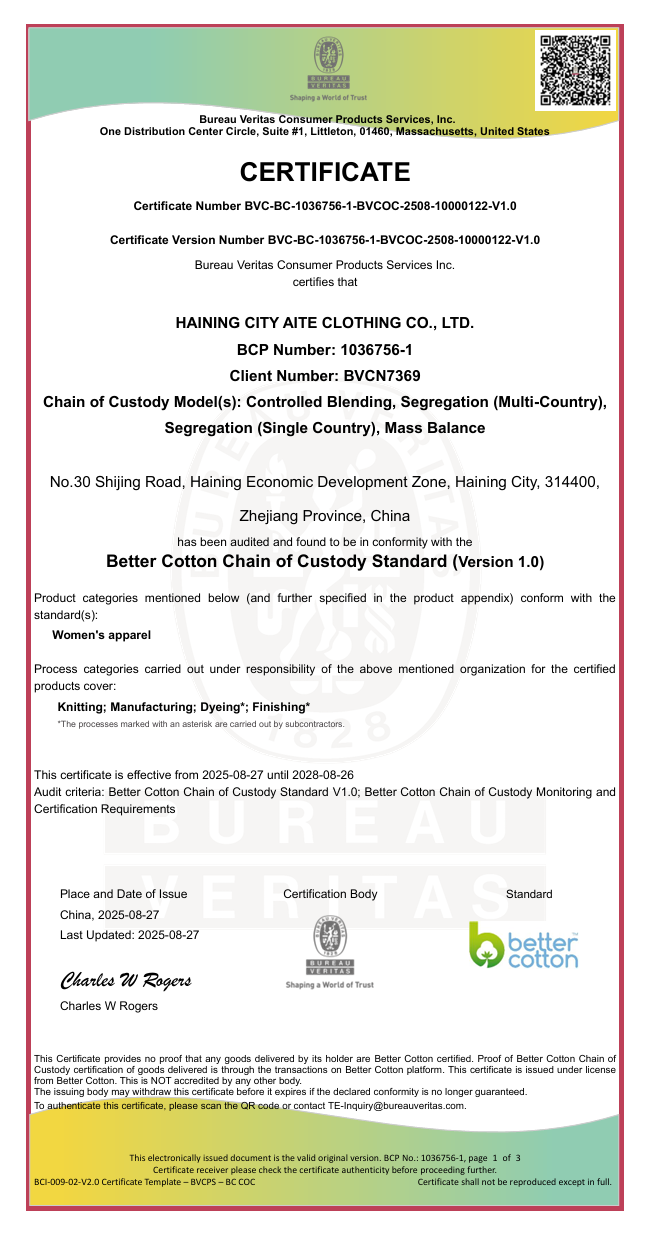

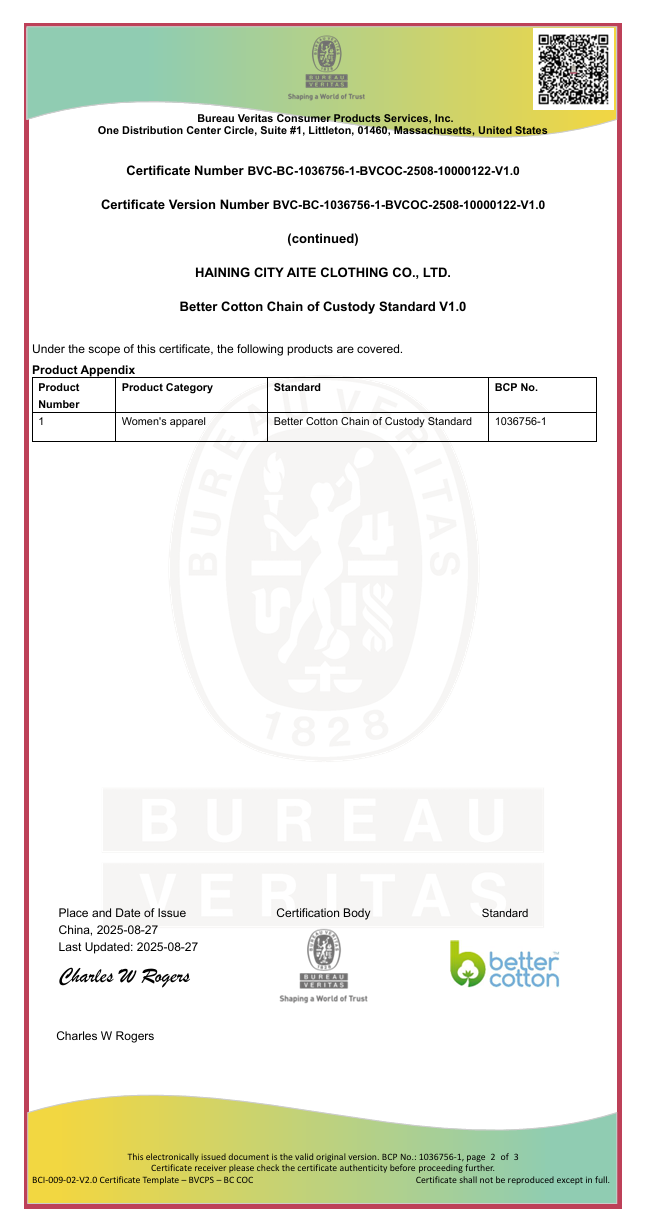

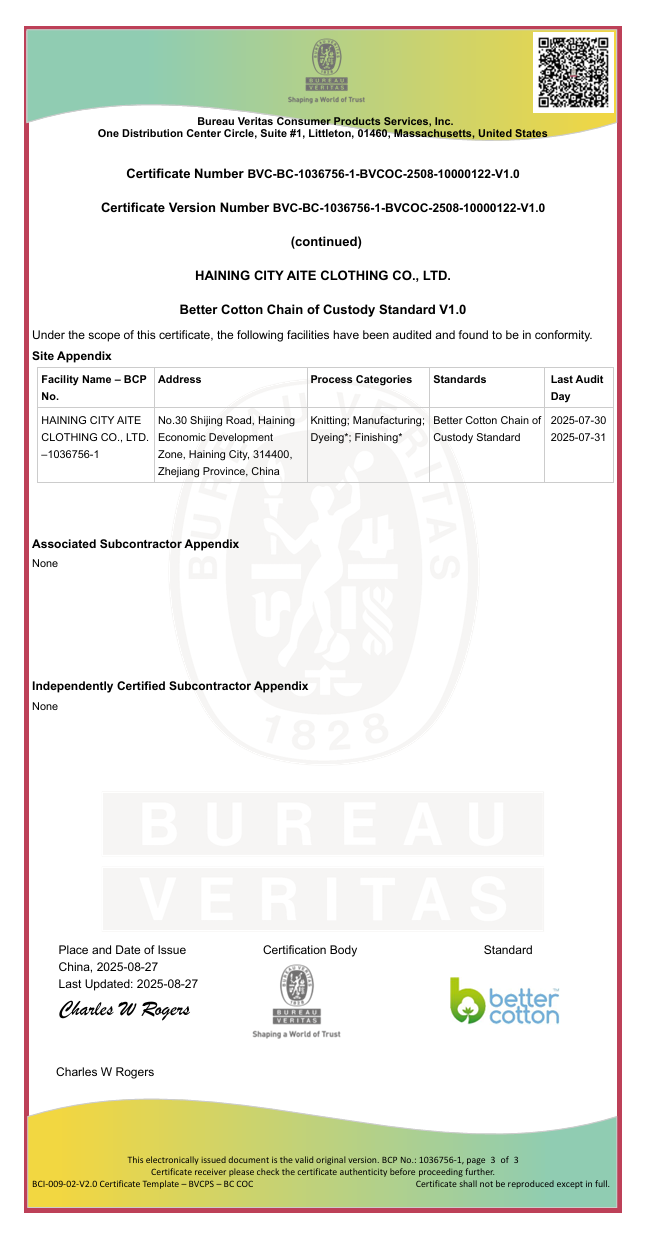

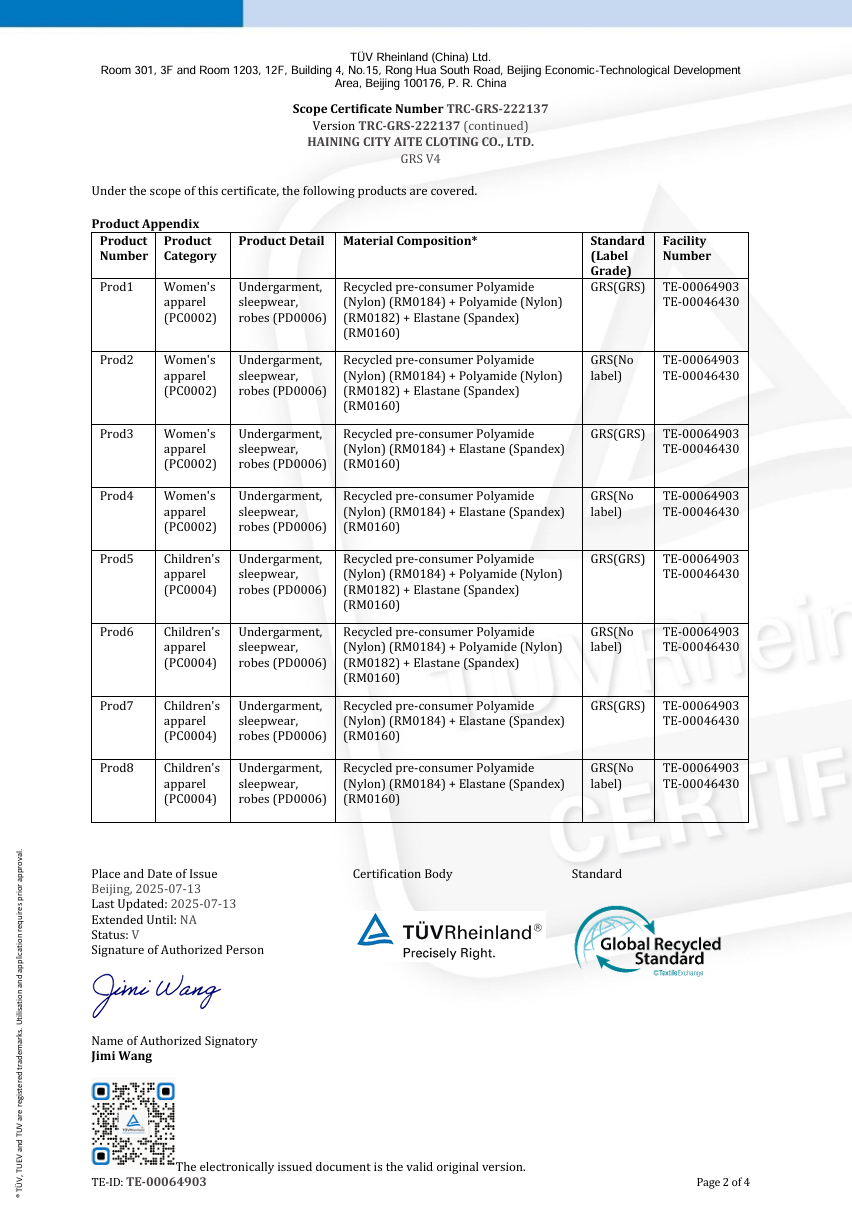

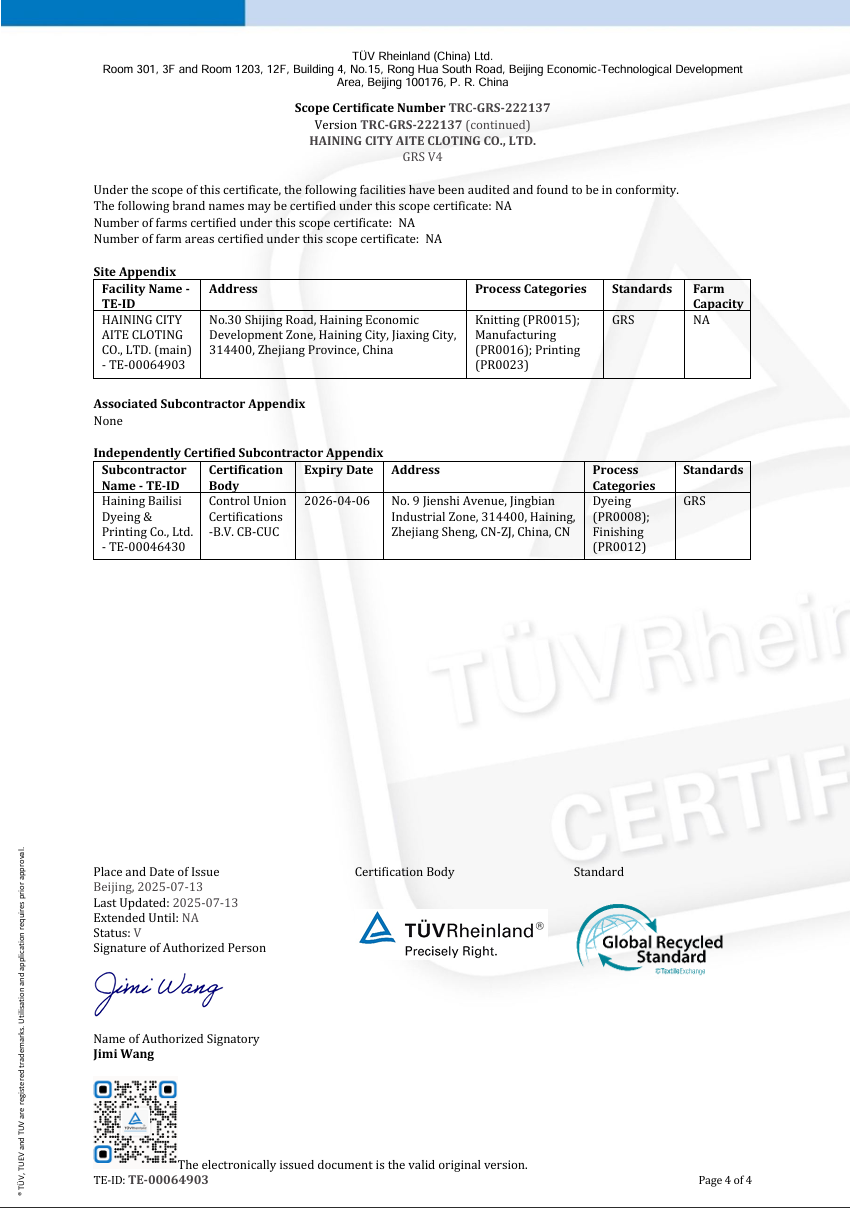

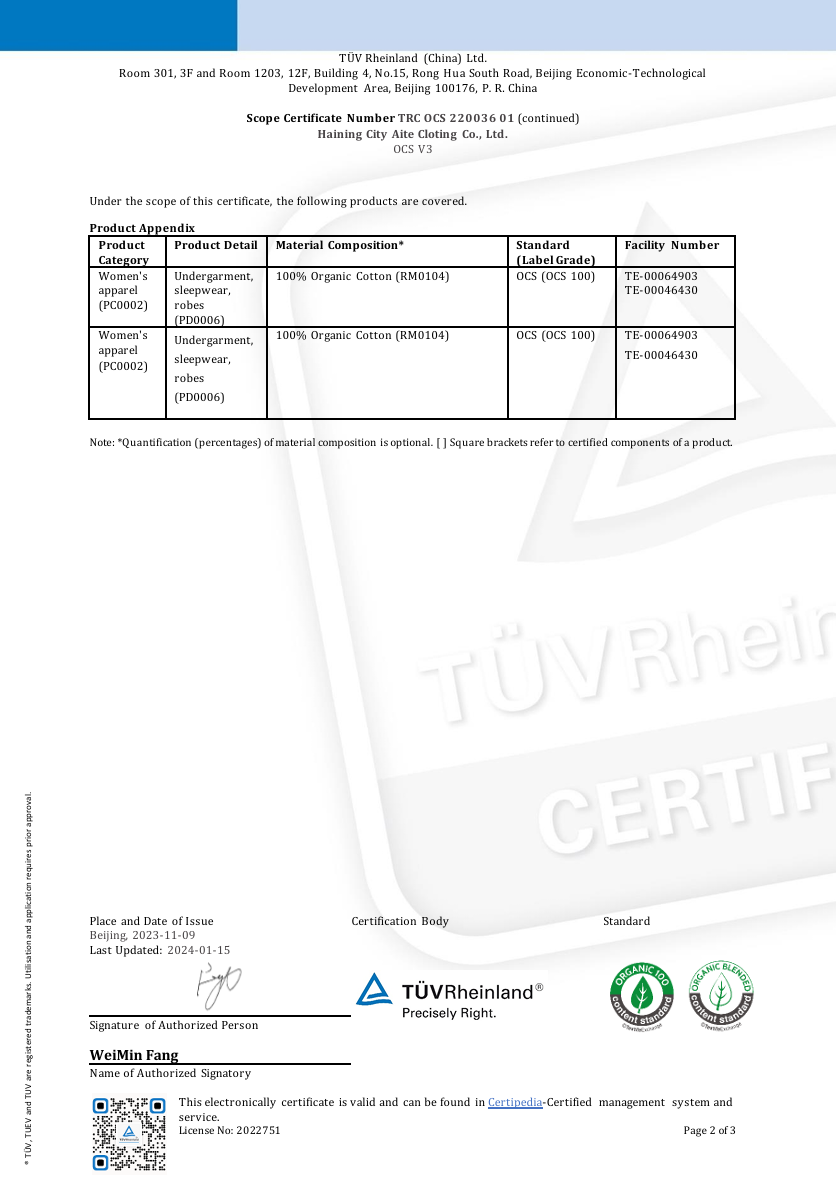

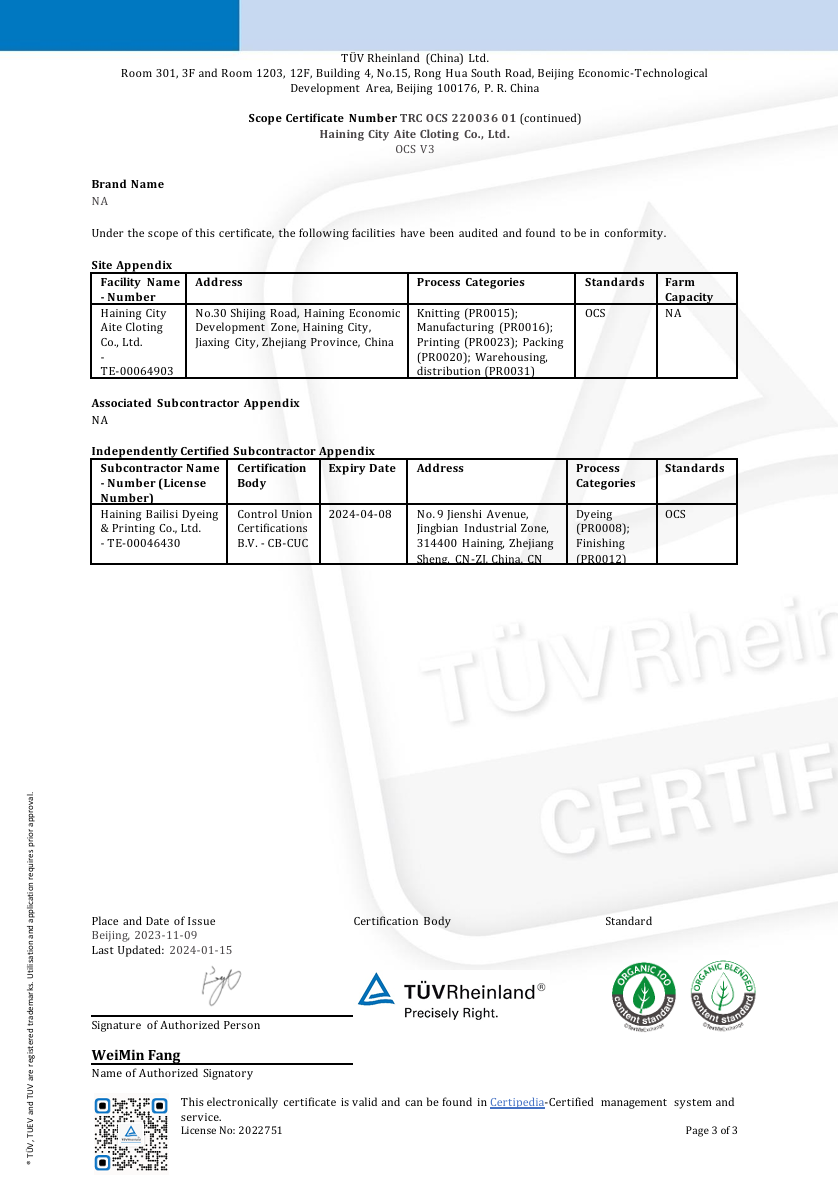

We are GRS (Global Recycled Standard) and OCS (Organic Content Standard) certified, amfori BSCI-audited, and Higg Index (FSLM) assessed, with Better Cotton Chain of Custody (CoC) to ensure material integrity from yarn to finished goods. A structured quality system (IQC–IPQC–FQC–OQC) and AQL shipment inspection to customer standards ensure consistent results.

Certificate Display

Manufacturing Process Flow

Yarn Preparation for Seamless Knitting (ACY/SCY)

PA6/PA66 or PET filaments are combined with spandex via air-covered (ACY)/core-spun (SCY) processes to build elastic, dye-friendly functional yarns. Cone winding and oiling are then applied to control package density, oil pick-up and tension uniformity, securing stable loop length and low end-breaks for high-speed seamless circular knitting with full batch traceability.

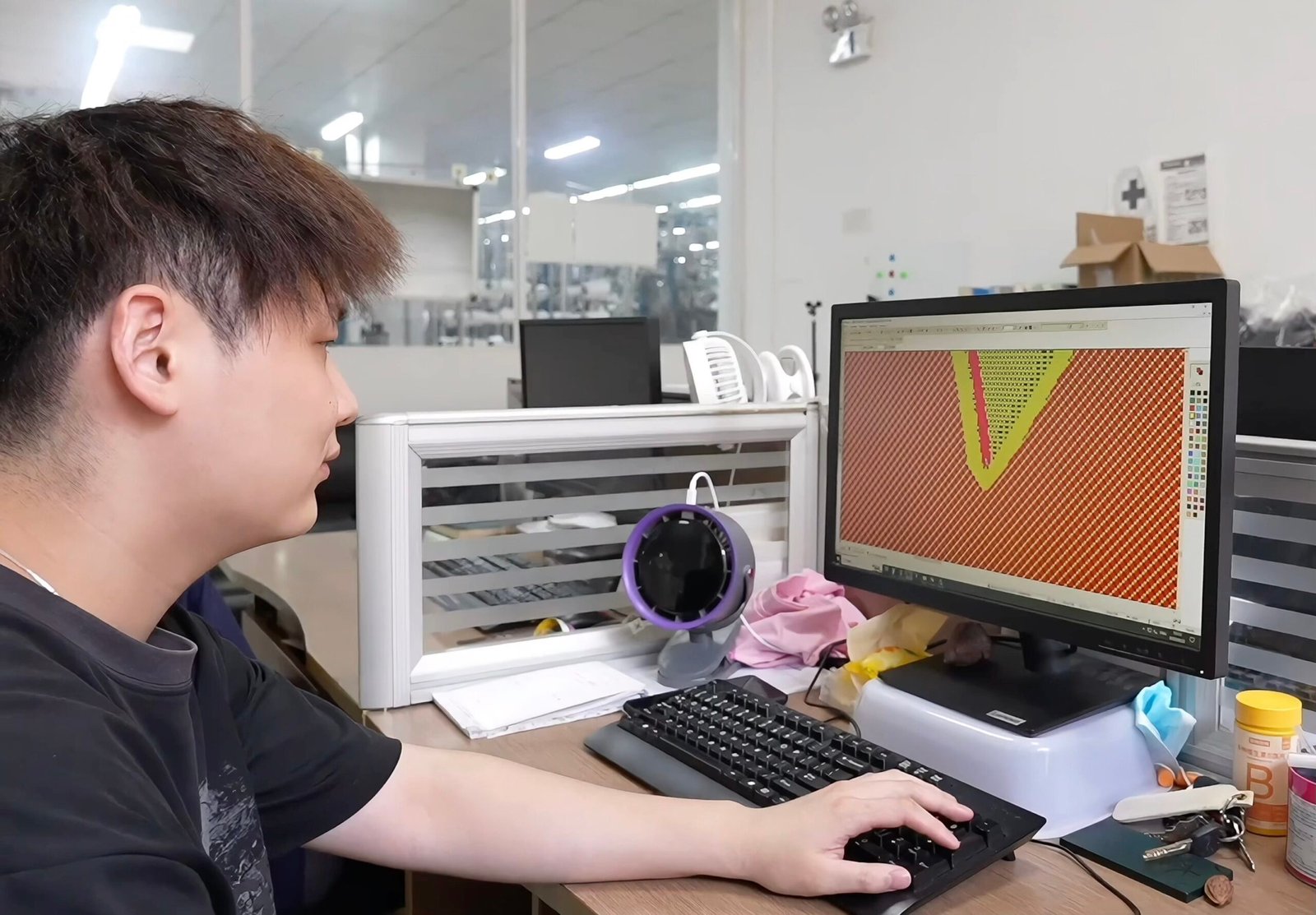

Seamless Product Design (BigBang / Photon) & Machine Program (D3p)

We use BigBang/Photon to build body-mapping and stitch layouts. Loop length, density (GSM), plating and knit/tuck/miss rules are parameterized by gauge (E18–E28) and cylinder size, validated with A/B swatches and DFM review. Approved settings are exported as D3p machine code to electronic jacquard seamless machines, with density/size charts and version control for sampling-to-mass consistency.

Seamless Mechanical Production (Circular Knitting Line)

After D3p code is verified, the line performs changeover & first-article inspection and then runs to takt. Positive feeders and closed-loop tension keep yarn delivery stable, while yarn-break/missing-needle auto-stops and patrol checks reduce defects. Run data (loop length, tension, speed, downtime codes) streams to MES; SPC guards size/hand-feel drift with process locks per the routing sheet.

Greige Handling & Pre-Finishing

After knitting, tubular greige pieces are batch-tagged and relaxed, then scoured/de-oiled and loosely dried to avoid marks. A heat-setting step (material-specific window) stabilizes dimensions and shrinkage before dyeing. Final 4-point inspection plus dimension/GSM/elastic-recovery checks are performed, followed by grading and full traceability for dyeing or secondary finishing.

Pattern Making

Although the tubular body is seamless, gussets, liners, bonding reinforcements, pockets and transfer positions require physical patterns. Patterns are derived from the finished-size spec, back-calculated with shrink/heat-set coefficients and zone-wise negative ease. Wale/course orientation, alignment notches and tolerances are defined, and boundaries are aligned with the knit body-mapping.

Cutting & Kitting

Cutting is executed from the approved patterns, then parts are kitted by size and workstation. Marker optimization maximizes yield while enforcing wale/course orientation and defect avoidance. Stretch fabrics are cut with low tension; nylon/polyester edges may be hot-knife/laser sealed. Small parts are die-cut for consistency, large parts cut by straight/band knife with controlled lay height. Post-cut, pieces are counted, bundled and labeled for full traceability.

Sewing & Assembly

Lightweight sewing joins gussets, liners, elastics and trims using flatseam, overlock and coverstitch. Differential feed and low thread tension, together with ball-point needles and soft filament threads, keep seams flat, chafe-free and matched to fabric stretch/recovery. Stress points are bartacked; bonding/ultrasonic may be applied for seam-free areas. SPI, thread tension and seam allowance are tightly controlled, with thread trimming and seam locking for a clean, next-to-skin finish.

Bartacking (Reinforcement Stitch)

At high-stress points we apply bartacks—short, dense stitch patterns that lock the seam and prevent tearing. Typical locations include seam ends, pocket openings, strap/elastic anchors, and gusset corners. A computerized bartack machine with a clamp/template executes the specified pattern. Critical controls: bartack length/width and stitch density (set per spec), upper/lower thread tension, clean thread trimming, accurate placement, and a flat, skip-free appearance. Strength samples are verified before release.

Heat Transfer & Bonding

Applying a tagless heat-transfer label or bonded reinforcement onto the seamless garment on a flat-bed heat press, controlling temperature–time–pressure and alignment for a flat, durable finish.

Final Pressing & Shaping

On a vacuum table, a steam iron is used to spot-press necklines, cuffs and hems, flatten seams and set the shape. Control temperature–time–pressure with rapid suction cooling; use a PTFE (Teflon) soleplate cover or cover cloth to prevent shine and impressions on nylon/spandex underwear, avoiding pull-induced distortion.

Final Quality Inspection

On illuminated inspection tables, each garment is checked by lot and size: first appearance (stains, snags, skipped stitches, bonding/transfer lift), then key measurements (chest, body length, hem) against the tolerance sheet, followed by quick functional tests (seam stretch & recovery, bartack strength, heat-transfer peel). Finally, labels (size/hangtag/QR) are verified. Results are classified as pass / rework / hold with segregation. Lot release follows the AQL plan, and all data go to MES for full traceability and SPC trending.

Inner Packing

Flow: Final cleaning → standard folding → tags/size stickers/certificates as required → 100% barcode verification → place in recyclable (PCR) clear polybag → vent holes & safety warning if needed → seal and bundle by size/lot → move to storage.

Carton Packing & Ocean Freight

We pack in strong cartons kept ≤20 kg each. Goods are sorted by size/color, stacked neatly, and shaped areas protected with tissue/boards plus a desiccant. Cartons get an H-pattern seal and strapping; labels show PO, style, color, size run, carton No., pieces, GW/NW, and barcode. If pallets are used, loads are wrapped & secured. Before shipment we confirm terms and sailing schedule with the forwarder, submit the packing list and invoice, and load by the cut-off. During container loading we balance weight, add moisture guard and door protection, and record container No./seal No. with photos.

Frequently Asked Questions (FAQ)

Q1: Is “seamless” completely stitch-free?

A: The body is knitted as a tubular fabric with no side seams. Functional areas—such as gussets or straps—may require minimal stitching or heat-bonding for assembly.

Q2: Why is heat-setting necessary?

A: Heat-setting stabilizes dimensions and elastic recovery, reducing post-wash shrinkage and creasing. It’s a critical step for next-to-skin and performance garments.

Q3: Can spandex (elastane) be damaged during dyeing?

A: Proper control of bath pH, temperature, and dwell time, combined with compatible dye/chemical systems, prevents elastane degradation and avoids yellowing.

Q4: What are the lead times for sampling and bulk production?

A: Using standard yarns/colors, sampling takes 7–10 days; bulk production 20–35 days. Complex zoning and dark shades may require additional time due to dyeing/finishing.

Q5: Is the minimum order quantity (MOQ) negotiable?

A: Yes—project-based. Typical MOQ is 300–500 pcs per color/style, adjustable by season and capacity planning.

Q6: What functional zones can you produce?

A: Breathable mesh, rib support, light/moderate compression, bonded seam-free construction, and reflective or jacquard branding, among others.